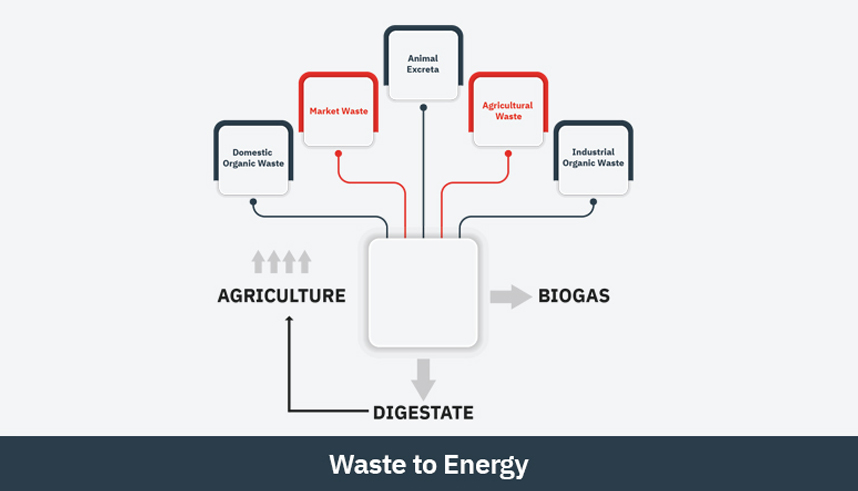

Waste to Energy

Paddy Straw to Bio-CNG

Plant Details

Plant Location: Ludhiana, Punjab

Output:

Biogas : 30000 cum/day

Bio-CNG : 12000 kg/day

Bio-Manure : 30 MT per day

Processing Capacity : 100 TPD Paddy straw

Raw material: Paddy Straw

Technology : AD process with pre-treatment of paddy straw to break the lignocellulosic material.

All proven and quality reliable products such as Agitators, Conveyors, Balloon, Grinders, Pumps etc.. imported from Germany, Belgium and Italy.

Paddy Straw/Other Agri Waste

Stubble burning is the deliberate setting fire of the straw stubble that remains after harvest.

Stubble burning affects the soil fertility resulting in loss of essential nutrients and also causes serious threat to human health including breathing problems, allergies and asthma.

Objective: To provide solutions for environmental problems due to stubble burning and improve the soil fertility there by supporting farmers.

Wheat/Paddy Straw/Agri Waste Biogas Project

2. Pre-treatment

- To make raw material suitable for biogas production

- To make Anaerobic digestion faster

- To increase biogas yield

Press Mud

Press-Mud: Press-mud is the compressed sugar industry waste produced from the filtration of the cane juice. Sugar mills in India produce about 12 million tonnes of press mud (filter cake) as a waste from double sulphitation processes.

Gas Yield potential: 90 to 115 cum/ton